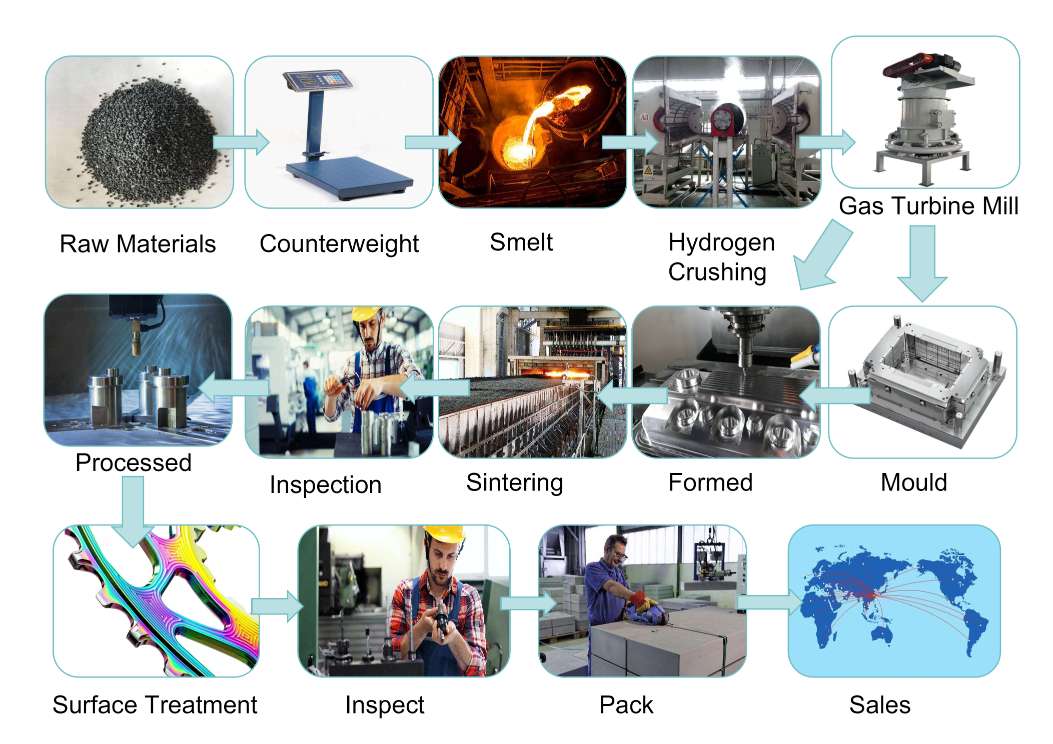

The process of manufacturing magnets encompasses several key stages to ensure high-quality results. It begins with material preparation, where the raw materials are carefully selected and prepped. This is followed by grinding, where the materials are finely processed to achieve the desired particle size.

In the mixing phase, these fine powders are combined in precise ratios to create a homogeneous mixture. The mixture is then subjected to pressing, where it is shaped into the desired form under high pressure.

Following pressing, the magnets undergo sintering, a crucial step involving high-temperature heating to fuse the material particles together, enhancing their magnetic properties.

Post-sintering, the magnets are machined to exact specifications, which may include coating for protection, drilling for functional applications, and any additional shaping needed.

Finally, the magnets go through rigorous final inspection to ensure they meet quality standards before being packaged for distribution. Each step is meticulously controlled to produce magnets that meet the highest standards of performance and reliability.

Simply fill out the form below as best you can. And don't sweat the details